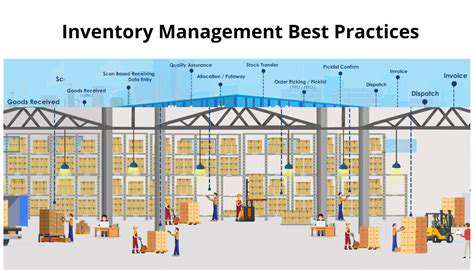

Optimizing Warehousing and Inventory Management

Optimizing Warehouse Layout for Efficiency

Warehouse design plays a pivotal role in operational fluidity and resource optimization. Strategic planning of movement patterns, storage solutions, and equipment placement forms the backbone of an efficient warehouse. Placing frequently ordered products closer to dispatch areas dramatically cuts down retrieval times while enhancing order processing speed. Intelligent use of shelving configurations and designated zones for various product categories further boosts operational output.

Forward-thinking designs that account for business growth prove invaluable. Adaptable layouts enable seamless expansion when needed, preventing costly and disruptive overhauls down the line. This foresight ensures warehouses can evolve alongside business needs without major operational interruptions.

Inventory Management Systems: A Key to Success

Modern inventory control systems are indispensable for maintaining optimal stock levels. Advanced tracking solutions provide minute-by-minute inventory visibility, eliminating both shortages and excess stock situations. This empowers businesses to make informed procurement and distribution decisions based on actual data rather than estimates.

Technologies like barcode readers and RFID tags have revolutionized stock monitoring, replacing error-prone manual counts with precise digital records. The automation of these processes significantly improves record accuracy while freeing staff for more critical tasks.

Warehouse Automation and Robotics

The introduction of automated systems and robotic assistance has transformed warehousing efficiency. Self-navigating vehicles handle internal transport operations, allowing human workers to concentrate on complex decision-making tasks. This optimized division of labor enhances productivity while reducing operational mistakes.

Robotic systems excel at repetitive tasks like item selection, packaging, and sorting, delivering unmatched speed and precision in order processing. Though the upfront investment appears substantial, the long-term gains in productivity and cost reduction typically justify the initial expenditure.

Demand Forecasting and Predictive Analytics

Precise demand prediction is critical for maintaining ideal inventory quantities. Examining past sales patterns, market shifts, and other influential factors enables businesses to project future needs with remarkable accuracy. This analytical approach minimizes the financial risks associated with inventory mismanagement.

Sophisticated predictive models can identify emerging trends before they become apparent. These analytical tools process vast amounts of sales data to generate reliable forecasts, enabling proactive inventory adjustments that prevent costly supply chain issues.

Supply Chain Visibility and Collaboration

Complete supply chain transparency is fundamental for warehouse optimization. Tracking shipments and inventory in real-time from origin to destination enhances coordination with all stakeholders. This level of visibility helps identify potential choke points before they cause delays.

Close cooperation with suppliers creates a synchronized approach to inventory control. Shared access to inventory data and demand projections facilitates more efficient supply chain planning and execution.

Safety and Security in Warehousing

A secure warehouse environment benefits both operations and personnel. Proper illumination, visible safety markings, and designated pathways significantly reduce workplace accidents. Regular safety training ensures all employees understand potential hazards and proper procedures.

Comprehensive security measures, including access controls and monitoring systems, protect valuable assets from theft or damage. These precautions safeguard investments while maintaining uninterrupted operations.

Sustainable Practices in Warehousing

Environmentally conscious operations are gaining importance in modern warehousing. Energy-saving lighting and equipment reduce both ecological impact and utility expenses. Using recyclable packaging materials and minimizing waste further supports sustainability goals.

Thoughtful warehouse designs that maximize natural lighting and airflow can substantially decrease energy needs. These eco-friendly approaches demonstrate corporate responsibility while improving operational efficiency.

Transforming Transportation and Delivery

Revolutionizing Last-Mile Delivery

Next-generation connectivity enables groundbreaking advances in final delivery stages. Autonomous aerial delivery vehicles could soon bring packages directly to consumers within minutes, while self-navigating ground vehicles promise to transform urban logistics. These innovations are transitioning from theoretical concepts to practical solutions that offer faster, more reliable, and eco-friendly delivery options.

Live tracking and adaptive routing systems allow delivery providers to respond instantly to changing conditions. This flexibility results in shorter delivery windows and happier customers. The potential for customized delivery options tailored to individual preferences creates new opportunities for enhancing customer satisfaction.

Optimizing Warehouse Operations

Next-gen connected warehouses achieve remarkable automation levels. Instant data sharing between robotic systems, transport vehicles, and human operators streamlines inventory control and order processing. This seamless coordination reduces errors while boosting productivity and cutting costs.

Advanced connectivity supports sophisticated predictive modeling in warehouse management. By combining historical patterns with real-time data, facilities can predict demand variations, optimize inventory, and prevent potential operational issues before they occur.

Enabling Enhanced Fleet Management

Connected vehicle technology enables comprehensive fleet monitoring and control. Performance metrics, fuel efficiency data, driver analytics, and environmental conditions can be analyzed to optimize routes, enhance safety, and reduce expenses. This comprehensive oversight facilitates preventive maintenance, minimizing vehicle downtime.

Additionally, advanced connectivity supports next-generation safety systems and autonomous driving features that improve road safety. The ability for vehicles, infrastructure, and other transportation elements to communicate creates transformative possibilities for fleet operations.

Improving Customer Experience

The customer service benefits of advanced logistics are equally significant. Real-time shipment tracking, personalized updates, and interactive delivery tools provide customers with unprecedented visibility and control. This transparency builds trust and strengthens brand loyalty.

Instant delivery notifications and flexible scheduling options via mobile apps represent just the beginning of customer service enhancements. These capabilities allow logistics providers to create seamless, satisfying experiences that encourage repeat business.

Promoting Sustainability in Logistics

Advanced logistics networks offer substantial environmental benefits. Optimized routing, reduced fuel usage, and streamlined operations collectively decrease ecological impact. The ability to analyze traffic flows and weather patterns enables further route optimization and emission reduction.

By leveraging cutting-edge technology, logistics companies can implement greener practices across their operations. This environmental commitment will become increasingly important as sustainability concerns continue growing among consumers and investors.

Communication methods have undergone radical transformation in recent years. Where physical mail and landline phones once prevailed, we now operate in a world of instant messaging and crystal-clear video conferencing. This connectivity revolution has fundamentally altered human interaction patterns, enabling near-instantaneous global communication. International business agreements now conclude virtually, while geographically separated families maintain daily contact through digital platforms.