The Dawn of Mechanization

Early forms of automation, dating back centuries, focused primarily on repetitive tasks in manufacturing. Simple machines, like water wheels and windmills, automated tasks such as grinding grain and powering looms. These innovations demonstrated humanity's enduring quest to reduce manual labor and boost efficiency. Though primitive, early automation dramatically enhanced productivity and set the stage for more advanced systems.

The steam engine revolutionized automation by introducing a powerful new energy source. This breakthrough enabled larger, more intricate machines, marking a pivotal shift from water and wind power to steam-driven industrial automation. This transition was instrumental in sparking the Industrial Revolution.

The Rise of the Assembly Line

The 20th century saw automation accelerate with Henry Ford's assembly line. By breaking production into repetitive steps, this method skyrocketed efficiency and output. The assembly line redefined manufacturing and consumerism, becoming the gold standard for mass production.

However, this innovation brought challenges like worker alienation and repetitive stress injuries. While specialization and rigid processes were necessary, the assembly line's transformative impact on productivity and economic growth remains undeniable.

The Digital Revolution

Computers and digital technologies ushered in a new automation era. Digital controls enabled unprecedented precision and flexibility, shifting from mechanical to digital systems. This integration allowed for intricate manufacturing processes, revolutionizing production capabilities.

Early CAD and CAM systems automated design and manufacturing, opening new innovation pathways despite their initial limitations.

The Internet of Things

IoT has further transformed automation through interconnected devices. Sensors and actuators enable real-time monitoring and control, boosting efficiency and predictive maintenance across industries.

Artificial Intelligence Integration

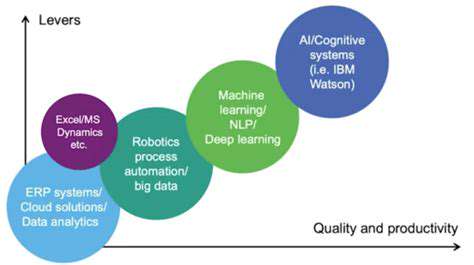

AI is reshaping automation by enabling systems to learn and adapt. Machine learning analyzes vast datasets to optimize processes and predict maintenance needs. AI-powered automation will continue evolving, impacting sectors from healthcare to customer service. Its potential warrants careful consideration as this technology advances.

Future Trends and Implications

The convergence of robotics, AI, and IoT will drive more sophisticated autonomous systems. This presents both opportunities and challenges as society adapts to automation's expanding role.

Ethical considerations like job displacement and economic inequality require proactive solutions to ensure automation benefits all.

Demystifying Intelligent Automation: Key Components

Intelligent Automation's Foundation: Robotic Process Automation (RPA)

RPA forms intelligent automation's core through software robots mimicking human actions. These bots interact with applications, extract data, and execute workflows. While powerful for streamlining, RPA lacks cognitive understanding. Its ease of implementation makes it ideal for rule-based processes.

Beyond the Rules: Cognitive Automation

Cognitive automation incorporates AI technologies like machine learning and natural language processing. This enables systems to handle complex, unstructured data and make informed decisions.

Data as Fuel: The Role of Data in Intelligent Automation

High-quality data powers cognitive automation. Robust data infrastructure ensures accurate insights and operational efficiency. Data validation processes are critical for reliable system performance.

The Human Element: Collaboration and Skill Development

Intelligent automation augments rather than replaces human capabilities. Upskilling initiatives in data analysis and process improvement are essential for workforce adaptation.

Overcoming Challenges and Implementing IA Successfully

Overcoming Obstacles in Implementation

Successful implementation requires anticipating technical challenges and stakeholder resistance. Early identification of potential issues enables effective contingency planning.

Importance of Planning and Preparation

Detailed project plans with clear objectives and timelines help navigate implementation challenges. Strategic resource allocation prevents bottlenecks.

Effective Communication and Collaboration

Transparent communication among stakeholders ensures alignment. Team collaboration fosters innovative problem-solving approaches.

Risk Assessment and Mitigation Strategies

Comprehensive risk analysis identifies potential implementation hurdles, allowing for proactive mitigation measures.

Adaptability and Flexibility

Successful implementation requires adjusting strategies to evolving circumstances. Continuous monitoring ensures timely course corrections.