Automated Control and Optimization of Water Distribution

Automated Control Systems: A Foundation

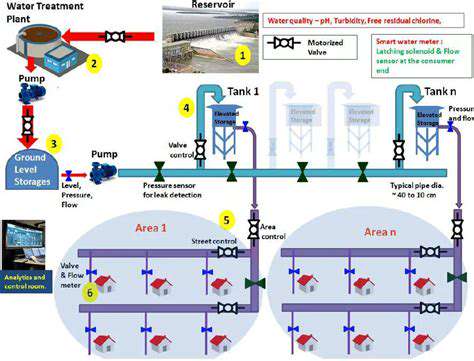

Automated control systems are critical in modern industrial processes, enabling precision, efficiency, and safety. These systems use sensors to monitor key parameters, such as temperature, pressure, and flow rate, and then use algorithms to adjust actuators to maintain desired conditions. This continuous feedback loop allows for dynamic responses to changing conditions, leading to optimized performance. The benefits extend beyond simply maintaining stable conditions; they allow for real-time adjustments to improve efficiency and reduce waste.

From simple on/off control loops to complex model predictive control strategies, the range of automated control techniques is vast. Each approach is tailored to the specific needs of the process being controlled, ensuring optimal performance and minimizing downtime. This approach is significantly different from manual control, where human operators rely on experience and intuition, and often struggle to maintain consistent quality and safety.

Optimization Techniques: Driving Efficiency

Optimization techniques are integral to automated control, pushing systems beyond basic control to achieve optimal performance. These techniques utilize mathematical models of the process to identify the best possible operating conditions. By considering various constraints and objectives, optimization algorithms can find the ideal settings that maximize output, minimize energy consumption, or achieve other desired outcomes. For instance, in a manufacturing process, optimization can determine the ideal speed of machinery to maximize production while minimizing wear and tear.

Advanced optimization algorithms, such as genetic algorithms and simulated annealing, can explore a vast solution space to find globally optimal solutions. This is particularly useful in complex systems where numerous variables interact and the ideal solution isn't immediately apparent. These sophisticated algorithms are critical for achieving true process optimization.

Applications in Diverse Industries

Automated control and optimization are not limited to a single industry; their applications are widespread. In manufacturing, these systems improve production efficiency, reduce waste, and ensure consistent product quality. In energy production, they optimize energy output while minimizing environmental impact. In food processing, they maintain food safety and quality standards.

The use of these systems in various domains is constantly expanding, leading to significant improvements in efficiency, safety, and sustainability. The integration of these technologies has the potential to dramatically alter the way industries function, creating more productive and environmentally conscious operations. This underscores the importance of understanding and implementing these control strategies in modern businesses.

Future Trends and Challenges

The future of automated control and optimization is marked by advancements in sensor technology, data analytics, and artificial intelligence. These advancements promise to enable more sophisticated control strategies and more precise optimization solutions. The integration of machine learning algorithms opens the door to predictive maintenance, proactive troubleshooting, and real-time adaptation to changing conditions.

However, challenges remain. These include the complexity of implementing and maintaining sophisticated systems, the need for skilled personnel to operate and maintain them, and the potential for system failures. Overcoming these challenges will require continued investment in research and development, as well as the development of robust safety protocols and training programs for personnel.