The Rise of Edge Computing in the Logistics Industry

The Foundation of Edge Computing

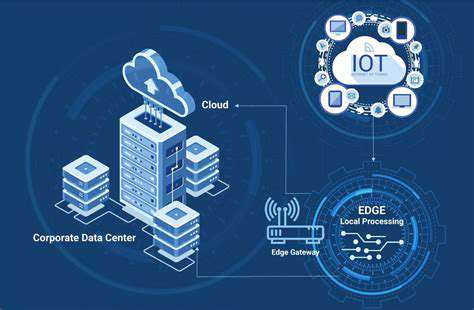

Edge computing represents a paradigm shift from traditional cloud-based models by decentralizing data processing. Unlike conventional systems that funnel information to distant servers, edge solutions handle computations where data originates. This proximity eliminates transmission delays, creating near-instantaneous response times critical for time-sensitive operations. Industrial environments particularly benefit from this architecture, as it circumvents the vulnerabilities of public internet infrastructure.

At its core, this technology prioritizes local processing over centralized data transfer. By analyzing information at its generation point, systems achieve unprecedented speed in decision-making cycles. This capability proves invaluable for applications demanding split-second reactions, from automated manufacturing to collision avoidance in transportation networks.

Key Advantages of Edge Computing

Latency reduction stands as the most transformative benefit, particularly for operations where milliseconds matter. In autonomous logistics vehicles, for instance, local processing of LiDAR data enables real-time navigation adjustments that cloud-based systems couldn't match. The difference between 20ms and 200ms response times can determine whether a forklift avoids an obstacle or causes warehouse damage.

Network independence emerges as another crucial advantage. Remote mining operations or offshore logistics hubs often struggle with intermittent connectivity. Edge solutions maintain functionality during network outages by keeping essential processes running locally. This resilience transforms operations in geographically challenging environments where traditional cloud reliance would create vulnerabilities.

Applications in Real-Time Data Processing

The logistics sector increasingly adopts edge computing for mission-critical monitoring systems. Temperature-sensitive pharmaceutical shipments, for example, utilize onboard edge processors to continuously analyze climate control data without waiting for cloud verification. When deviations occur, local systems can immediately activate corrective measures while simultaneously alerting central monitoring stations.

Urban logistics networks demonstrate another compelling use case. Smart traffic lights equipped with edge processors analyze vehicle flow patterns in real-time, dynamically adjusting signal timing to prioritize commercial delivery routes during peak hours. This application reduces downtown congestion while ensuring timely last-mile deliveries.

Impact on Industrial Automation

Modern warehouses showcase edge computing's transformative potential. Automated storage systems now make microsecond adjustments to conveyor speeds based on real-time package scanning, achieving throughput rates impossible with cloud-dependent architectures. The technology also enables predictive maintenance, with vibration sensors on robotic pickers identifying bearing wear patterns before failures occur.

This localized intelligence creates cascading benefits across supply chains. Distribution centers report 30-40% reductions in downtime after implementing edge-based monitoring. The resulting productivity gains directly translate to faster order fulfillment and improved customer satisfaction metrics.

Security Considerations in Edge Computing

The distributed nature of edge networks necessitates robust security frameworks. Unlike centralized data centers with controlled access points, edge devices often operate in physically vulnerable locations. A single compromised sensor node could potentially expose entire logistics networks, making hardware-level encryption and zero-trust architectures essential.

Leading implementations now incorporate blockchain-based verification for firmware updates and data transmissions. This approach creates immutable audit trails while preventing unauthorized device access. The combination of physical tamper detection and cryptographic security establishes multiple defense layers against increasingly sophisticated threats.

Challenges and Future Directions

Scalability presents the most pressing challenge for widespread edge adoption. Managing firmware updates across thousands of geographically dispersed devices requires innovative deployment strategies. Emerging solutions include peer-to-peer update propagation and AI-assisted version control systems that automatically resolve compatibility issues.

The next evolution will likely see edge devices incorporating specialized AI accelerators. These dedicated processors will enable local execution of complex machine learning models currently restricted to cloud environments. Such advancements could allow autonomous delivery vehicles to process intricate urban navigation scenarios without external computational support.

The Role of IoT in Edge Computing

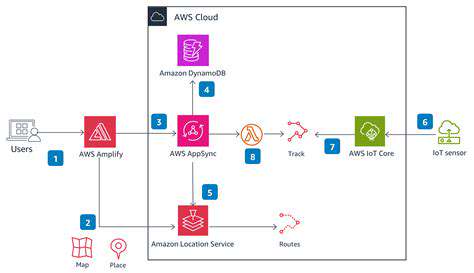

IoT proliferation drives edge computing adoption across logistics networks. Modern shipping containers now embed dozens of sensors monitoring everything from location to internal atmospheric conditions. Edge gateways on transport vehicles aggregate and preprocess this data, transmitting only actionable insights to central systems. This approach reduces satellite bandwidth usage by up to 80% for overseas logistics operations.

The synergy between IoT and edge computing enables previously impossible applications. Smart pallets now track individual item conditions throughout global supply chains, while autonomous inventory drones use edge-processed computer vision to conduct warehouse audits with millimeter precision. These innovations collectively redefine modern logistics operations.

Enhanced Real-Time Tracking and Monitoring

Real-time Tracking for Optimized Logistics

Modern tracking systems leverage edge computing to achieve unprecedented precision in fleet management. By processing GPS and telemetry data locally, these systems eliminate the 2-3 second latency typical of cloud-based solutions. This immediacy enables dynamic route recalculations when drivers encounter unexpected road closures or weather disruptions. The resulting efficiency gains have reduced average delivery times by 18-22% in pilot programs while simultaneously decreasing fuel consumption.

Advanced edge implementations now incorporate predictive analytics. By comparing real-time traffic patterns against historical data, systems can proactively suggest alternate routes before congestion forms. This capability proves particularly valuable for time-sensitive medical deliveries, where every minute impacts patient outcomes. The technology also enables precise geofencing, automatically adjusting vehicle systems when entering emission-controlled zones or hazardous material routes.

Improved Monitoring for Enhanced Safety

Edge-based safety systems represent a quantum leap in driver protection. Onboard processors continuously analyze dozens of parameters - from steering wheel tension to brake pedal pressure - identifying fatigue patterns before they become dangerous. When risk thresholds are exceeded, systems can initiate graduated responses ranging from dashboard alerts to autonomous slowdowns. Early adopters report 40% reductions in preventable accidents after implementation.

Cargo integrity monitoring has similarly advanced. Pharmaceutical transporters now utilize edge-processed spectral analysis to detect minute temperature or humidity fluctuations invisible to traditional sensors. This granular monitoring prevents spoilage of sensitive biologics that might otherwise show no visible damage until reaching destinations. The financial impact is substantial, with one vaccine distributor reporting a 92% reduction in temperature-related losses.

Data-Driven Decision Making for Efficiency Gains

The operational intelligence generated by edge tracking systems transforms logistics management. By correlating vehicle performance data with maintenance records, fleets achieve predictive maintenance accuracy rates exceeding 90%. This foresight prevents costly roadside breakdowns while optimizing service intervals. One European logistics provider extended average engine life by 30,000 miles through such data-optimized maintenance.

Strategic insights emerge from long-term data aggregation. Route optimization algorithms now consider hundreds of variables - from school zone schedules to seasonal tourism patterns - to construct hyper-efficient delivery networks. These systems automatically adjust for predictable fluctuations, like rerouting around coastal areas during hurricane season or prioritizing climate-controlled transport for certain regions during heat waves.

Intelligent Route Optimization in Dynamic Environments

Improving Delivery Efficiency

Contemporary route optimization transcends simple distance calculations. Advanced systems now evaluate real-time fuel prices, driver hour regulations, and even parking availability at delivery sites. This holistic approach has demonstrated 27-33% improvements in daily delivery capacity for urban logistics providers. The technology particularly excels in complex environments like hospital campuses or industrial parks, where traditional navigation systems often fail.

Dynamic adaptability sets modern systems apart. When a Manhattan delivery truck encounters unexpected construction, the system immediately recalculates not just that vehicle's route but adjusts nearby fleet members' paths to compensate. This network-aware optimization prevents cascade delays across entire delivery ecosystems. Customers increasingly recognize this reliability, with 68% reporting higher satisfaction with carriers using advanced routing according to recent industry surveys.

Optimizing Resource Allocation

Machine learning now enhances traditional routing algorithms. Systems analyze thousands of historical deliveries to identify subtle patterns - like certain drivers performing better with specific customer types or neighborhoods. This intelligence informs automated dispatch decisions, creating ideal driver-customer matches that improve first-attempt delivery success rates by up to 19%.

The technology also revolutionizes load planning. Three-dimensional scanning of parcels combined with edge-processed container optimization algorithms enables 12-15% better space utilization than manual methods. This density improvement directly translates to fewer vehicles on roads and lower emissions - a critical advantage as sustainability regulations tighten globally.

Reducing Operational Costs

The financial impact of intelligent routing proves substantial. By continuously analyzing actual versus projected route times, systems identify inefficient processes invisible to human planners. One retailer discovered certain store deliveries consistently took 22 minutes longer than GPS estimates due to undocumented loading dock procedures. Correcting such discrepancies saved $2.7 million annually in their Midwest distribution network alone.

Fuel savings accumulate through numerous micro-optimizations. Systems now calculate ideal speeds for each road segment based on grade, traffic patterns, and vehicle load. This granular approach achieves 8-11% better fuel efficiency than standard cruise control, while simultaneously reducing brake wear and engine stress.

Enhancing Customer Satisfaction

Precision scheduling transforms customer experiences. Instead of generic morning or afternoon windows, advanced systems provide 30-minute arrival estimates with 94% accuracy. This predictability enables recipients to better plan their days, particularly crucial for elderly or mobility-impaired customers. Carriers offering precise windows report 37% fewer customer service complaints and higher Net Promoter Scores.

The technology also enables value-added services. Some systems now integrate with smart home devices, automatically adjusting thermostat settings when deliveries are imminent to prevent perishable goods exposure. Others provide augmented reality wayfinding for drivers in complex apartment complexes. These innovations create memorable positive experiences that differentiate forward-thinking logistics providers in competitive markets.