Optimizing Supply Chains and Manufacturing Processes

Optimizing Procurement Processes

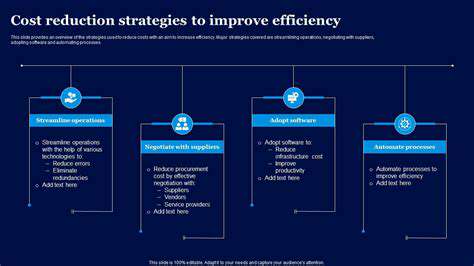

Effective procurement strategies are crucial for optimizing supply chains. A well-defined procurement process, from identifying supplier needs to evaluating and selecting vendors, can significantly reduce costs and improve efficiency. This involves evaluating various factors such as supplier reliability, quality, and delivery times. Streamlining the process and utilizing technology like e-procurement systems can automate tasks and reduce manual errors, leading to substantial cost savings and improved responsiveness.

Implementing a robust supplier relationship management (SRM) program is essential. This includes ongoing communication, performance monitoring, and collaboration to ensure that suppliers meet agreed-upon quality and delivery standards. Developing strong relationships with key suppliers fosters trust and can lead to mutually beneficial outcomes.

Improving Inventory Management

Effective inventory management is fundamental to minimizing storage costs and preventing stockouts. Accurate forecasting of demand and implementing just-in-time (JIT) inventory systems can reduce holding costs and improve cash flow. Utilizing inventory management software and implementing real-time tracking systems helps ensure that the right products are available at the right time, minimizing disruptions to production and delivery schedules.

Implementing a robust system for tracking inventory levels, demand patterns, and lead times is essential for optimizing inventory. Regularly reviewing and adjusting inventory levels based on changing demand and supply conditions is vital to maintaining optimal stock levels.

Enhancing Logistics and Transportation

Optimizing logistics and transportation networks is key to efficient and cost-effective delivery of goods. Strategic partnerships with reliable transportation providers and the use of advanced routing algorithms can significantly reduce transportation costs and delivery times. Implementing real-time tracking and monitoring systems for shipments improves transparency and allows for proactive adjustments to potential delays or issues.

Exploring alternative transportation modes, such as rail or intermodal freight, can also provide cost savings and reduce the environmental impact of transportation. Careful consideration of packaging and handling procedures can minimize damage during transit, reducing the need for costly repairs or replacements.

Leveraging Technology for Automation

The use of technology, including Enterprise Resource Planning (ERP) systems and other advanced software, can automate many supply chain processes. This automation can enhance efficiency and accuracy, reducing errors and improving overall productivity. Utilizing data analytics and machine learning algorithms can provide insights into patterns and trends in demand, enabling proactive adjustments to supply chain operations.

Promoting Sustainability

Integrating sustainability into supply chain strategies is increasingly important for businesses committed to environmental responsibility and social impact. Considering the environmental footprint of suppliers and transportation methods, and adopting eco-friendly packaging solutions are crucial for reducing the carbon footprint. Implementing sustainable sourcing practices and promoting ethical labor standards are vital for long-term success.

Implementing Agile and Flexible Strategies

Adapting to market changes and unexpected disruptions requires a flexible and agile supply chain. By embracing agile methodologies, businesses can better respond to fluctuations in demand and supply, ensuring that operations remain resilient. This includes establishing contingency plans for potential disruptions, fostering collaboration with suppliers, and developing alternative sourcing options. Furthermore, fostering adaptability in the supply chain is crucial for resilience in the face of future uncertainty.

The Future of Industrial Innovation

The Rise of AI-Powered Automation

Artificial intelligence (AI) is rapidly transforming industrial processes, leading to unprecedented levels of automation. AI-driven systems can analyze vast amounts of data to optimize production lines, predict equipment failures, and even automate complex tasks previously requiring human intervention. This automation promises increased efficiency, reduced downtime, and a significant boost in overall productivity. AI-powered robots and systems are becoming increasingly sophisticated, capable of performing intricate movements and adapting to changing conditions in real-time.

Sustainable Practices and Circular Economy

The future of industrial innovation is inextricably linked to sustainability. Industries are increasingly embracing circular economy models, aiming to minimize waste and maximize resource utilization. This shift involves rethinking production processes to prioritize reuse, repair, and recycling, ultimately reducing the environmental footprint of manufacturing.

Advanced Materials and Manufacturing Techniques

The development of new and advanced materials is driving innovation in manufacturing. Materials with enhanced strength, durability, and conductivity are enabling the creation of more efficient and resilient products. These advancements are also opening doors for new manufacturing techniques, such as 3D printing and additive manufacturing, which offer unparalleled flexibility and precision in design and production. This allows for customized products and reduced material waste.

The Internet of Things (IoT) Integration

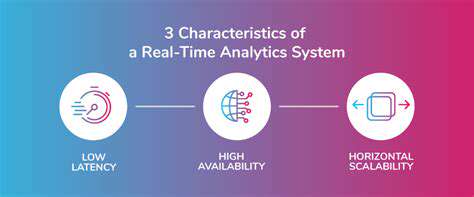

The Internet of Things (IoT) is revolutionizing industrial operations by connecting machines and equipment to a network. This connectivity allows for real-time monitoring, data collection, and analysis of industrial processes. This data-driven approach enables predictive maintenance, optimized resource allocation, and improved overall operational efficiency. The ability to remotely monitor and control equipment significantly enhances productivity and reduces downtime.

Cybersecurity and Data Protection

As industrial systems become increasingly interconnected, cybersecurity is becoming a critical concern. Protecting sensitive data and preventing cyberattacks is paramount to maintaining operational stability and preventing costly disruptions. Industries are investing heavily in robust cybersecurity measures to safeguard their systems and sensitive data. Robust cybersecurity protocols are essential for maintaining the integrity and reliability of industrial operations. Failure to address these issues could have significant consequences for both businesses and consumers.

Big Data Analytics and Predictive Modeling

Big data analytics is playing a crucial role in enabling predictive modeling for various industrial applications. By analyzing vast amounts of data from diverse sources, businesses can identify patterns, predict future trends, and make more informed decisions. This data-driven approach allows for proactive problem-solving and optimized resource allocation, thus enhancing overall efficiency and profitability. This approach can be used to forecast demand, optimize inventory management, and streamline supply chains.

Human-Machine Collaboration

The future of industrial innovation isn't solely about automation; it's also about fostering collaboration between humans and machines. The ideal scenario involves human operators leveraging the capabilities of AI and automation tools to enhance their own productivity and decision-making processes. This symbiotic relationship between humans and machines will be crucial to maximizing efficiency and adaptability in evolving industrial landscapes. Ultimately, this collaboration will enable greater innovation and productivity for the future of work in the industrial sector. Integrating human ingenuity with technological advancements will be critical for success.