The Growing Need for Real-Time Decision-Making

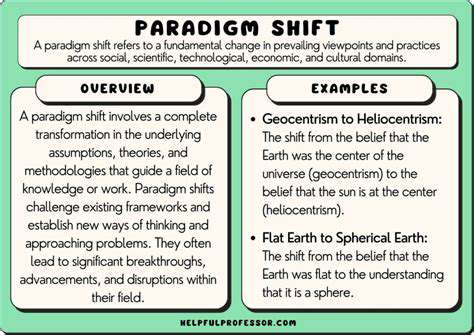

Modern logistics faces unprecedented challenges as customer expectations evolve. The industry must now process information instantaneously while maintaining flawless execution. Unlike traditional centralized systems that often lag behind, decentralized intelligence solutions bring computation power directly to where it's needed most. This paradigm shift enables split-second adjustments that keep deliveries on schedule despite unpredictable variables like traffic or weather. Operators gain the ability to reroute shipments dynamically while maintaining transparency throughout the supply network.

Instantaneous data interpretation has become the lifeblood of efficient distribution networks. Sophisticated algorithms now parse information from multiple streams - including vehicular telemetry, atmospheric conditions, and package status updates. Such granular visibility separates industry leaders from competitors still relying on outdated methods. When a delivery truck encounters unexpected road closures, the system doesn't just react - it anticipates alternative solutions before the driver recognizes the need.

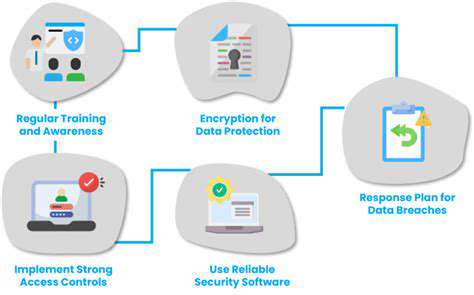

Enhanced Security and Fraud Prevention

Contemporary supply chains face sophisticated threats that demand equally advanced countermeasures. Intelligent monitoring systems now scrutinize every access point, analyzing behavioral patterns that might indicate malicious intent. These systems don't just record footage - they interpret visual data in context, distinguishing between routine activities and genuine security concerns. Local processing ensures immediate threat assessment without waiting for distant servers to analyze the situation.

Anomaly detection has reached new levels of precision through continuous machine learning. When packages exhibit unusual weight fluctuations or unexpected route deviations, the system flags these irregularities immediately. This proactive surveillance model prevents losses before they occur rather than simply documenting them afterward. The financial impact of such prevention extends far beyond the value of individual shipments, preserving brand reputation and customer trust.

Improving Operational Efficiency and Cost Savings

Automated intelligence transforms logistics economics by eliminating wasteful practices. Vehicles no longer traverse suboptimal routes, maintenance occurs precisely when needed, and human oversight focuses exclusively on exceptions rather than routine operations. These cumulative efficiencies create financial advantages that compound over time throughout the entire distribution network. The result is a leaner, more responsive operation that delivers measurable improvements to the bottom line.

Equipment reliability reaches new heights through continuous condition monitoring. Rather than following arbitrary maintenance schedules, repairs occur based on actual usage patterns and performance metrics. This data-driven approach prevents both premature servicing and catastrophic failures, maximizing asset utilization. Delivery fleets achieve higher uptime while simultaneously reducing maintenance expenditures through precisely timed interventions.

Resource deployment becomes a dynamic calculation rather than a static plan. The system continuously rebalances personnel assignments and vehicle allocations based on real-time demand fluctuations. Empty miles disappear from route plans as algorithms identify opportunities to consolidate shipments or redirect assets based on shifting priorities throughout the operational day.

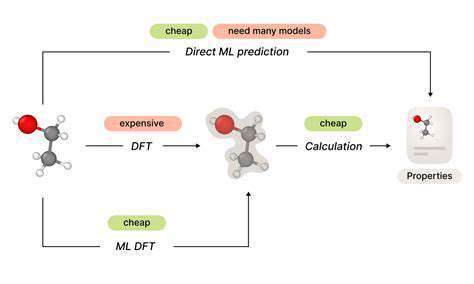

Predictive Maintenance and Enhanced Safety Features

Predictive Maintenance: Proactive Solutions

Modern maintenance strategies have evolved beyond calendar-based servicing. Today's intelligent systems monitor component wear in real time, correlating operational data with failure probabilities. This approach transforms maintenance from a cost center to a strategic advantage, ensuring maximum equipment availability precisely when needed. In distribution networks where minutes translate to monetary value, such precision creates competitive differentiation.

The contrast with traditional methods couldn't be more stark. Where reactive maintenance addressed breakdowns and scheduled maintenance followed arbitrary intervals, predictive systems intervene exactly when necessary. This optimization extends asset lifespans while simultaneously reducing unplanned downtime - a dual benefit that reshapes operational economics across the entire logistics sector.

Enhanced Safety Features: Improving Operational Security

Safety systems now incorporate behavioral analytics that identify risks before they materialize. By analyzing driving patterns, load securement metrics, and environmental conditions, these solutions predict hazardous situations with remarkable accuracy. The system might detect subtle signs of driver fatigue or recognize when cargo requires repositioning long before human observers would notice these concerns.

These protective measures safeguard both personnel and merchandise throughout the distribution cycle. Cargo worth millions benefits from constant digital guardianship that never sleeps or becomes distracted. The financial implications extend beyond loss prevention to include reduced insurance premiums and improved regulatory compliance.

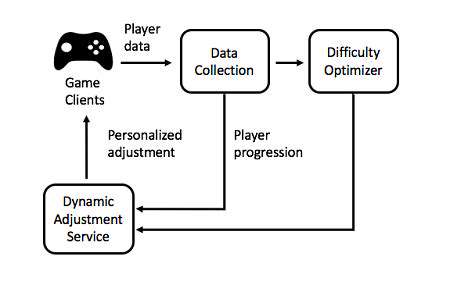

Improved Resource Allocation and Optimization

Dynamic resource management has become a reality through continuous data synthesis. The system evaluates personnel availability, vehicle capacity, and package volumes to create optimal distribution patterns that adapt minute-by-minute. This fluid approach to logistics planning would overwhelm human planners but represents the natural operating mode for intelligent distribution networks.

Real-Time Visibility and Tracking: Enhanced Transparency

End-to-end shipment visibility now provides stakeholders with an unprecedented operational picture. From manufacturer to end consumer, every touchpoint generates data that feeds into a cohesive tracking system. This transparency enables proactive exception management rather than reactive problem-solving, fundamentally changing how supply chains operate.

Automated Decision-Making: Streamlined Processes

Routine operational choices now occur automatically based on predefined parameters and machine learning insights. The system handles thousands of micro-decisions daily - routing adjustments, load balancing, and priority sequencing - that collectively determine operational efficiency. Human oversight focuses instead on strategic considerations and exception management, creating a more effective division of responsibilities.

Data-Driven Insights for Future Planning

Historical operational data becomes predictive intelligence through advanced analytical techniques. These insights inform everything from fleet expansion decisions to seasonal staffing requirements, creating a planning framework rooted in empirical evidence rather than intuition. The resulting forecasts achieve unprecedented accuracy, allowing logistics providers to align resources precisely with anticipated demand.

Reduced Costs and Increased Efficiency: Driving Profitability

The financial benefits of intelligent logistics systems manifest across every operational metric. Maintenance costs decline as interventions become more precise, fuel efficiency improves through optimized routing, and labor productivity increases through better task allocation. These compounded efficiencies create a sustainable competitive advantage that competitors cannot easily replicate. The result is a logistics operation that delivers superior service at lower cost - the ideal combination in any competitive market.

The Future of Logistics and Supply Chains: Embracing Edge AI

The Rise of Automation in Logistics

Automation now permeates every logistics function, from warehouse robotics to autonomous delivery vehicles. These technological advances create operational synergies that manual processes could never achieve. The integration of machine intelligence transforms static distribution networks into adaptive systems that continuously self-optimize. What once required human oversight now occurs autonomously, freeing managerial attention for higher-value strategic decisions.

The implications extend far beyond labor savings. Automated systems operate with precision that eliminates the variability inherent in human performance, creating consistently reliable operations that scale effortlessly. This reliability becomes increasingly valuable as customer expectations continue rising in competitive markets.

Sustainable Practices in Supply Chains

Environmental responsibility now drives operational decisions alongside traditional cost considerations. Route optimization algorithms factor carbon emissions alongside fuel costs, while packaging solutions balance protection with recyclability. These sustainable practices no longer represent optional corporate social responsibility - they've become essential components of brand identity and customer preference.

The shift toward greener operations yields unexpected benefits beyond environmental impact. Efficient routing reduces wear on vehicles, sustainable packaging often proves more cost-effective long-term, and eco-conscious consumers demonstrate greater brand loyalty. Sustainability and profitability increasingly align rather than conflict in modern logistics operations.

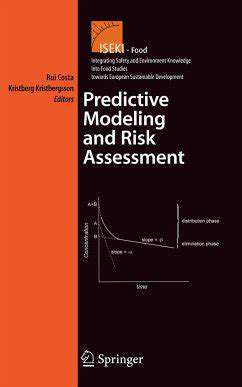

The Importance of Data Analytics

Operational data has transformed from record-keeping to strategic asset. Advanced analytics uncover patterns invisible to human analysts, revealing opportunities for improvement across every logistics function. These insights drive continuous refinement of processes, creating a culture of perpetual optimization that keeps pace with evolving market demands.

Predictive modeling has become particularly valuable for inventory management, where the cost of miscalculation can devastate profitability. By correlating sales data with external factors like weather patterns or economic indicators, logistics providers achieve stocking precision that minimizes both shortages and excess inventory.

The Impact of E-commerce on Logistics

Explosive e-commerce growth has reshaped distribution networks fundamentally. The expectation of rapid delivery now requires inventory positioning strategies radically different from traditional retail models. This shift has birthed innovative solutions like micro-fulfillment centers and crowdsourced delivery networks that redefine last-mile logistics.

Meeting e-commerce demands requires rethinking every aspect of logistics operations. Warehouse layouts prioritize rapid picking over bulk storage, delivery networks emphasize flexibility over consistency, and customer communication becomes as critical as physical delivery. These adaptations continue evolving as online shopping behaviors mature and change.

The Growing Role of Technology in Visibility

Modern tracking technologies provide granular visibility that was unimaginable just years ago. Stakeholders can monitor not just shipment locations but environmental conditions, handling events, and estimated time of arrival with remarkable precision. This transparency creates trust across supply chains while enabling proactive issue resolution before customers ever become aware of potential problems.

The value chain benefits from shared visibility that aligns incentives and improves coordination. Manufacturers adjust production based on real-time inventory data, retailers optimize promotions using current stock positions, and logistics providers balance resources according to immediate needs rather than forecasts.

The Future of Global Trade and Logistics

International commerce continues evolving in complexity, requiring logistics networks capable of navigating regulatory variations, trade agreements, and geopolitical shifts. Future supply chains will likely emphasize regional resilience alongside global connectivity, creating hybrid models that balance efficiency with risk mitigation.

The ability to reconfigure distribution networks rapidly will separate market leaders from followers. As trade patterns shift unexpectedly, logistics providers must demonstrate agility in rerouting shipments, repositioning inventory, and adapting procedures to maintain seamless operations across borders.