The Future of Smart Factories and Beyond

The Rise of Automation

Smart factories are increasingly reliant on automation, employing robots and sophisticated machinery to perform repetitive tasks with greater speed and precision. This automation streamlines production processes, leading to significant gains in efficiency and productivity. By automating mundane tasks, human workers can focus on more complex and strategic roles, fostering innovation and problem-solving within the factory environment.

The integration of robotic arms, automated guided vehicles (AGVs), and advanced control systems is transforming manufacturing landscapes. These advancements allow for 24/7 operation, minimizing downtime and maximizing output. Furthermore, the ability to dynamically adjust production lines based on real-time data is a key advantage of automation in smart factories.

Data-Driven Decision Making

Smart factories leverage vast amounts of data generated by various sensors and machinery. This data is crucial for optimizing production processes, predicting potential issues, and making informed decisions about resource allocation. By analyzing this data, companies can pinpoint bottlenecks, identify areas for improvement, and develop proactive strategies to enhance overall performance.

Real-time data analysis empowers factory managers to make data-driven decisions that impact everything from inventory management to quality control. This proactive approach significantly reduces waste and improves the overall profitability of the operation. Predictive maintenance, enabled by data analysis, is another crucial aspect of this transformation.

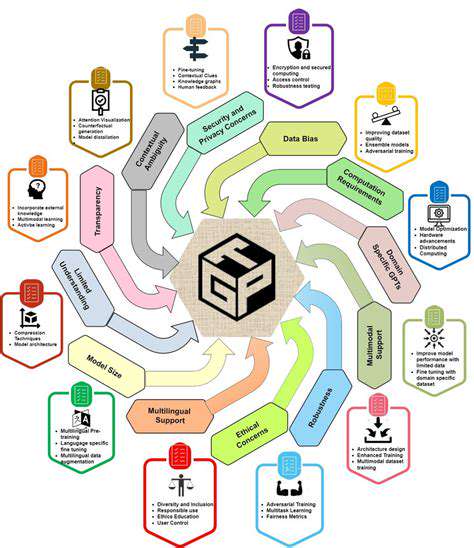

Enhanced Cybersecurity Measures

With the increasing connectivity of smart factory components, cybersecurity becomes a paramount concern. Protecting sensitive data and maintaining the integrity of operational systems is critical to ensuring uninterrupted production and preventing malicious attacks. Robust cybersecurity measures must be implemented to safeguard against cyber threats and maintain the confidentiality and integrity of data.

Advanced security protocols, including intrusion detection systems, firewalls, and regular vulnerability assessments, are essential for mitigating risks. Implementing zero-trust security architectures and multi-factor authentication for access control are additional strategies to enhance the overall cybersecurity posture of the smart factory environment.

Improved Worker Safety and Wellbeing

Smart factories can contribute to a safer and more comfortable work environment for employees. By integrating safety sensors and real-time monitoring systems, potential hazards can be identified and addressed promptly. This proactive approach reduces the risk of accidents and injuries, improving the overall safety record of the factory.

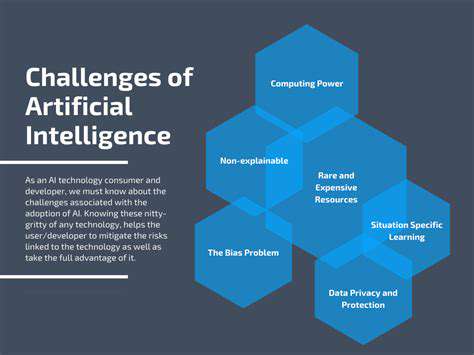

The Role of Artificial Intelligence

Artificial intelligence (AI) plays a pivotal role in the advancement of smart factories. AI-powered systems can automate complex tasks, predict equipment failures, and optimize production processes. AI-driven insights can be applied to a wide range of industrial applications, including quality control, predictive maintenance, and supply chain optimization.

Machine learning algorithms can analyze data from various sources to identify patterns and anomalies, allowing for proactive intervention and improved decision-making. This leads to a more efficient and responsive manufacturing process.

Sustainable Practices in Smart Factories

Sustainability is becoming increasingly important in the manufacturing sector. Smart factories can integrate environmental monitoring systems to track energy consumption and waste generation. Using data insights, companies can optimize resource usage and identify opportunities for reducing their environmental footprint.

Implementing sustainable practices not only minimizes the environmental impact but also enhances the reputation and competitiveness of the company. This includes adopting renewable energy sources, optimizing energy efficiency through smart controls, and minimizing waste generation throughout the production cycle.