The Transformative Power of AI in Modern Supply Chains

AI-Driven Visibility and Real-Time Tracking

Advanced AI algorithms enable unprecedented visibility across the entire supply chain. By analyzing vast amounts of data from various sources, such as sensors, logistics platforms, and weather forecasts, AI systems can predict potential delays, identify bottlenecks, and provide real-time tracking of shipments. This proactive approach to identifying and mitigating risks significantly improves the efficiency and responsiveness of the entire process, allowing companies to adjust their operations dynamically and maintain a high level of control over their goods in transit.

Predictive Analytics for Demand Forecasting

AI-powered predictive analytics offers a powerful tool for accurately forecasting future demand. By analyzing historical sales data, market trends, and external factors like economic conditions and seasonal variations, AI systems can provide highly accurate demand forecasts. This capability allows companies to optimize inventory levels, reduce waste, and ensure they have the right products in the right place at the right time. This proactive approach avoids stockouts and overstocking, saving significant costs and improving customer satisfaction.

Automated Order Processing and Fulfillment

AI can automate many aspects of order processing and fulfillment, significantly accelerating the entire cycle. From automated order routing and inventory management to intelligent picking and packing, AI systems can streamline operations and reduce human error. This leads to faster delivery times, improved order accuracy, and a significant reduction in operational costs. The implementation of robotic process automation (RPA) and machine learning (ML) models in fulfillment centers can be particularly impactful.

Optimized Inventory Management

AI-powered systems can optimize inventory management strategies, leading to significant cost savings and improved efficiency. By analyzing sales data, demand patterns, and supplier lead times, AI can predict optimal inventory levels, reducing storage costs and minimizing the risk of stockouts or overstocking. This intelligent approach to inventory management ensures that the right amount of inventory is available at the right time, maximizing resource utilization and minimizing waste.

Improved Supplier Relationship Management

AI facilitates better communication and collaboration with suppliers. By analyzing supplier performance data, AI systems can identify potential risks and opportunities, allowing companies to proactively address issues and build stronger, more reliable relationships. AI can also predict potential disruptions in the supply chain, such as supplier shortages or delays, enabling companies to develop contingency plans and mitigate risks, demonstrating a proactive approach to maintaining supply chain resilience.

Enhanced Customer Experience through Personalized Service

AI can personalize the customer experience throughout the supply chain, from order placement to delivery. By analyzing customer data, AI can anticipate customer needs and preferences, allowing companies to tailor their services and communications to provide a seamless and satisfying experience. This can include personalized delivery options, proactive communication about shipment updates, and tailored recommendations for future purchases. A more personalized approach fosters stronger customer relationships and loyalty.

Predictive Analytics for Proactive Inventory Management

Understanding Predictive Analytics

Predictive analytics is a powerful approach to business decision-making that leverages historical data to forecast future outcomes. It goes beyond simply analyzing past trends; it uses statistical algorithms and machine learning techniques to identify patterns and relationships within data, allowing businesses to anticipate potential future events and make proactive adjustments. This forward-looking capability is crucial for staying ahead of market fluctuations and competitive pressures. Predictive models can be used to predict various outcomes, from customer churn to product demand fluctuations.

By understanding the underlying factors driving these trends, businesses can adjust their strategies and operations accordingly. This allows for more informed decisions, reduced risks, and increased profitability.

Key Applications of Predictive Analytics

Predictive analytics has a wide range of applications across various industries. One key application is in customer relationship management (CRM). By analyzing customer data, businesses can predict customer behavior, identify potential churn risks, and tailor marketing strategies to retain valuable customers. This approach significantly reduces customer attrition and optimizes marketing spend.

Building Predictive Models

The process of building predictive models involves several key steps. First, the data needs to be collected, cleaned, and prepared for analysis. This often involves handling missing values, outliers, and inconsistencies in the data. Second, suitable predictive models are chosen based on the type of data and the desired outcome. Common models include regression analysis, classification algorithms, and time series forecasting methods. Third, the models are trained and evaluated using historical data to determine their accuracy and reliability.

Careful consideration of data quality and model selection is critical to ensuring accurate predictions. Failing to address these aspects can lead to flawed insights and poor decision-making.

Data Preparation and Feature Engineering

Data preparation is a crucial step in predictive analytics. It involves transforming raw data into a suitable format for model training. This includes handling missing values, converting categorical variables into numerical representations, and scaling numerical features to prevent features with larger values from dominating the model. Feature engineering, the process of creating new features from existing ones, can significantly improve model accuracy by capturing complex relationships within the data.

Evaluating and Validating Predictive Models

It's essential to rigorously evaluate and validate predictive models to ensure their accuracy and reliability. Various techniques can be employed to assess the model's performance, including metrics like accuracy, precision, recall, and F1-score. Cross-validation methods are used to prevent overfitting, ensuring the model generalizes well to unseen data. Regular monitoring and updates are crucial to maintain the model's effectiveness over time, as underlying patterns in the data may change.

Deploying and Monitoring Predictive Models

Once a predictive model is validated, it needs to be deployed into a production environment. This involves integrating the model into existing systems and workflows. Continuous monitoring of the model's performance is critical to identify any degradation in accuracy or unexpected changes in the data. This allows for timely adjustments to the model or data sources to maintain its effectiveness over time. Regular retraining and updates are necessary to reflect evolving business conditions and data patterns.

Automated Decision-Making for Enhanced Operational Efficiency

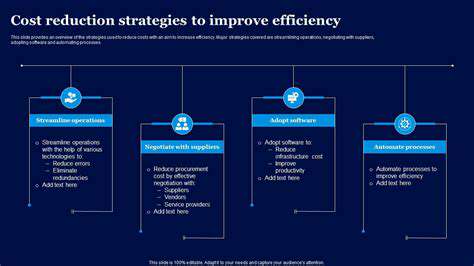

Optimizing Inventory Management

Automated decision-making systems are revolutionizing inventory management within supply chains. By analyzing real-time data from various sources, including sales forecasts, production schedules, and external market trends, these systems can dynamically adjust inventory levels. This proactive approach minimizes stockouts and reduces excess inventory, ultimately freeing up capital and minimizing storage costs. Predictive models, powered by AI, anticipate future demand fluctuations with remarkable accuracy, allowing companies to proactively adjust their inventory strategies and avoid costly disruptions.

Furthermore, automated systems can optimize storage locations based on product demand patterns. This strategic placement maximizes space utilization and minimizes the time it takes to locate and retrieve items, leading to significant improvements in order fulfillment efficiency. The result is a leaner, more responsive inventory management process that directly contributes to operational efficiency.

Predictive Maintenance for Equipment

AI-powered predictive maintenance systems analyze machine data to identify potential equipment failures before they occur. By monitoring vibration patterns, temperature fluctuations, and other key metrics, these systems can proactively schedule maintenance, minimizing downtime and preventing costly repairs. This proactive approach reduces the risk of unexpected equipment breakdowns, ensuring consistent operational output and reducing the need for expensive emergency repairs.

Streamlining Order Fulfillment

Automated systems can significantly enhance the efficiency of order fulfillment processes. They can dynamically route orders to the most efficient fulfillment centers, optimize packing procedures, and track shipments in real-time. These improvements translate to faster order processing times, reduced errors, and enhanced customer satisfaction. Real-time tracking also enables customers to monitor their shipments, providing a more transparent and responsive customer experience.

Automated Quality Control

AI-powered systems can automate quality control processes, ensuring consistent product quality and reducing defects. They can analyze images, videos, and other data to identify inconsistencies and defects, allowing for swift corrective action. This proactive approach minimizes the risk of faulty products reaching customers and protects brand reputation. Moreover, automated quality control helps to identify patterns in defects that might be missed by manual inspection, providing valuable insights for process improvement.

Dynamic Pricing Strategies

AI-powered systems can enable companies to implement dynamic pricing strategies that adapt to real-time market conditions. By analyzing competitor pricing, demand fluctuations, and other factors, these systems can adjust prices to maximize revenue and profitability. This dynamic approach allows companies to stay competitive and capitalize on market opportunities, while also mitigating the risk of underpricing.

Enhanced Supply Chain Visibility

Automated decision-making tools provide comprehensive visibility into the entire supply chain. By connecting various data sources, these systems offer real-time insights into inventory levels, order status, and transportation logistics. This transparency allows for faster problem identification and resolution, enabling companies to make data-driven decisions to optimize every aspect of their supply chain. Improved visibility empowers managers to pinpoint bottlenecks, anticipate potential disruptions, and react swiftly to changing market conditions.

Improved Collaboration and Communication

AI-powered platforms facilitate better collaboration and communication across different departments and stakeholders within a supply chain. By centralizing data and providing real-time updates, these systems foster a shared understanding of the current state of the supply chain. This streamlined communication process enhances coordination and reduces delays, leading to greater efficiency and responsiveness. Improved communication reduces the risk of miscommunication and streamlines the flow of information throughout the entire supply chain.

Real-Time Visibility and Enhanced Collaboration

Real-Time Data Stream

Real-time visibility into critical operational data is paramount for effective decision-making. This allows businesses to react swiftly to changing conditions and optimize processes in real-time. By having instant access to key performance indicators (KPIs), organizations can identify bottlenecks and address them proactively. This dynamic approach fosters a culture of continuous improvement and responsiveness.

The ability to observe data as it's generated provides a significant advantage. This capability empowers businesses to make informed decisions based on current trends, not historical data. real-time data streams enable businesses to swiftly adapt to market fluctuations and customer demands.

Improved Process Efficiency

Real-time visibility significantly enhances process efficiency by enabling quick identification and resolution of issues. This allows for prompt adjustments to workflows and resource allocation, minimizing downtime and maximizing output. Improved process efficiency translates directly into cost savings and increased profitability.

By identifying bottlenecks and inefficiencies as they arise, businesses can implement corrective actions immediately. This dynamic approach to process management fosters a culture of continuous improvement and optimization.

Enhanced Decision-Making

Real-time data provides the necessary insights for making well-informed decisions. This data-driven approach reduces reliance on guesswork and historical trends, leading to more accurate and timely strategic choices. Data-driven decision-making ensures that organizations are always responding to the most current information, leading to more effective strategies.

Access to real-time data empowers leaders to react swiftly to market changes and customer needs. This ability to make informed decisions in real-time is crucial for competitive advantage in today's fast-paced business environment.

Predictive Analytics Capabilities

Real-time data streams are essential for building predictive models. This allows for proactive identification of potential issues and opportunities, enabling preventative measures and strategic planning. Predictive analytics, powered by real-time insights, helps organizations stay ahead of the curve and anticipate future trends.

Organizations can leverage real-time data to identify patterns and anomalies that might indicate future problems or opportunities. This proactive approach allows for the development of strategies to address these issues or capitalize on these opportunities. By being able to predict future outcomes, businesses can make well-informed decisions that drive growth and success.

Enhanced Customer Experience

Real-time visibility enables a more responsive approach to customer needs. This dynamic approach to customer service facilitates faster issue resolution, improved communication, and a more personalized experience. Real-time data allows businesses to understand customer behaviour in real-time, leading to improved strategies to satisfy their needs.

By monitoring customer interactions and feedback in real-time, businesses can make adjustments to products, services, and processes to enhance customer satisfaction. This personalized approach to customer service fosters loyalty and strengthens brand reputation.

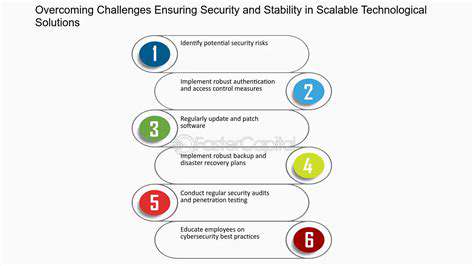

Security and Compliance

Real-time data necessitates robust security measures to protect sensitive information. This includes implementing strong authentication protocols, data encryption, and access controls to prevent unauthorized access or data breaches. Security and compliance are paramount when dealing with real-time data streams.

Ensuring the integrity and confidentiality of real-time data streams is crucial. This involves implementing advanced security protocols, rigorous data governance policies, and ongoing compliance checks to safeguard sensitive information.

Operational Optimization

Real-time visibility allows for immediate identification of operational inefficiencies and bottlenecks. This insight enables rapid adjustments to workflows, resource allocation, and processes to maximize efficiency and productivity. Real-time operational optimization allows businesses to react swiftly to issues and keep operations running smoothly.

By understanding operational performance in real-time, businesses can identify and address problems before they escalate. This allows for continuous improvement and ensures that operations are functioning at peak efficiency. Real-time data analysis is essential for optimizing operational efficiency and achieving greater productivity.